Bin Activator

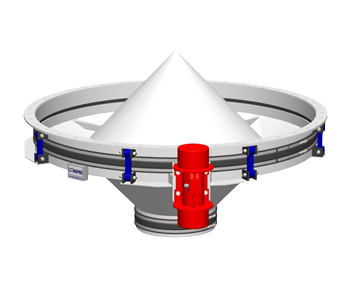

A Bin Activator, most Commonly known as a Vibrating Bin Discharger is installed below a storage Silo to ensure on-demand, trouble-free discharge of stored Dry Bulk solids.

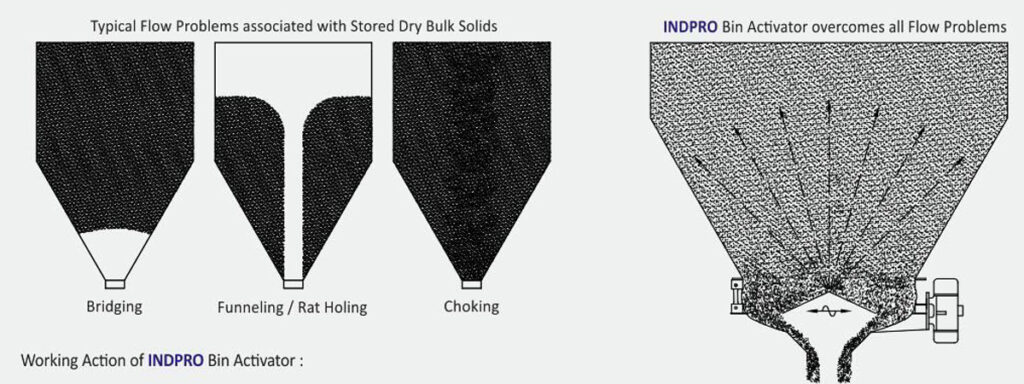

“INDPRO” Bin Activator is the Ultimate Solution to overcome Discharge Problems associated various types of stored Bulk Solids

Features

- Properly clamped Endless & reinforced Synthetic Rubber Sleeve to ensure zero leakage even for fine powders.

- Suspension Hangers :- One piece, rubber molded for vibration isolation and load bearing.

- Vibratory Motors :- ATEX / Ex /CE standard supply.

- Construction :- MS / SS304 / SS316One

- Power Supply :- 400 V / 3 Phase / 50 Hz. Standard or any other on request.

Bin Activator Commonly know as Vibratory Bin Discharger. “INDPRO” Bin Activator is the ultimate solution to overcome Discharge Problems of all types of stored Bulk Solids. They are available in a wide range is to take care of all the possible silo geometries and dimensions.

Available constructions are Carbon Steel, SS 304 / SS 316 with Glass Bead or Sanitary finish.

Bin Activator or Vibrating Bin Discharger for flour milling / spices / chemical / Cement industry :- “INDPRO” Bin Activator is the first choice of OEMs, Project Engineering Companies and End users. Expectations of competitive pricing with quality construction and durable performance in the needs of any user, and “INDPRO” Bin Activator is just the right choice to meet all of them. The entire construction of the “INDPRO” Bin Activator is so rugged that the user never ever bothers to maintain spares including rubber components.

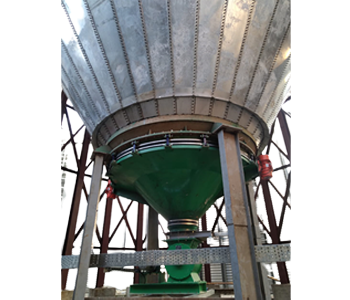

“INDPRO” Bin Activator under Conical Bottom GI Silo :- “INDPRO” Bin Activators, is a pioneer concept of use under a Conical Bottom GI Silo. The concept carries with a specially designed sealed Bin Activator mounting to safeguard vibration transmission to the silos. Suspension hangers can take any head load to give a long term sustainable solution.

“INDPRO” Bin Activator with a Unique Twin Outlet Design :- “INDPRO” Bin Activator can cater to 2 downstream process lines from One Silo. The unique design feature ensures equal discharge from both outlets. This is an extremely cost-effective solution where a big Silo is selected over two small silos with their individual filling mechanism.