Vibratory Screener:

Requirement of Vibratory Screening is demand of almost all industries handling bulk solids in their processes. “INDPRO” Vibratory Screens are manufactured only for specific process requirements like load head rooms / plastic pellet screening etc.

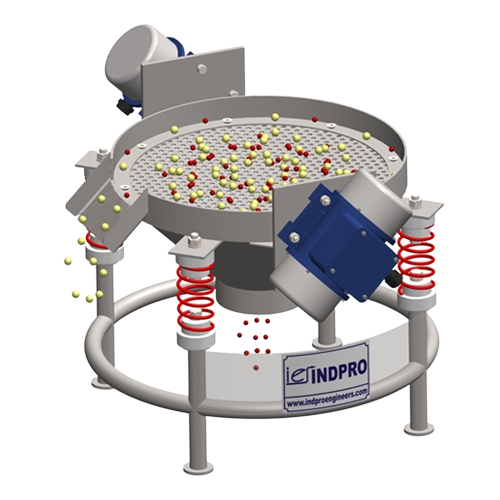

Vibratory Flow Thru Screener :-

Screening for oversized particles is very convenient while fines are collected in line.

“INDPRO” Vibratory Flow Thru Screeners run on vibrators mounted out of the main screening deck to produce required gyratory vibration pattern.

This is a tailor made, unique and compact design for a screening machine.

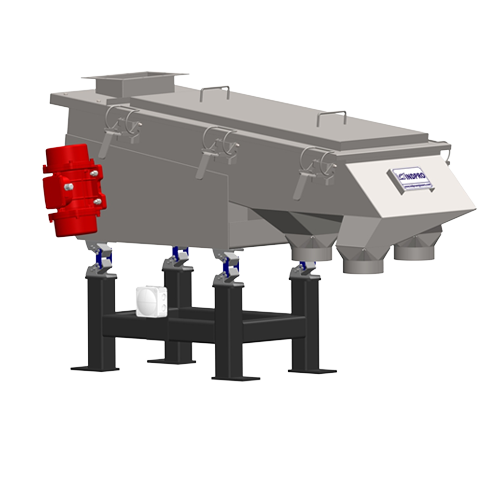

Vibratory Rectangular Screener :-

The equipment is specifically built for plastic compounding / masterbatch units. The logic of working is to use rectilinear vibratory patterns to remove fines and double or triple uncut strands.

“INDPRO” Vibratory Rectangular Screener is driven in a pure horizontal pattern of linear vibrations by a pair of contra-rotating vibratory motors. The screening decks are a single-piece construction of process required perforation grades. The entire assembly is clamped with special quick release latch locks to save time for cleaning during grade changes.

Vibratory Screener – “INDPRO” Vibratory Screeners are offered for various size separations of bulk solids.

a) Vibratory Screeners for Uncut Plastic Pellets :- “INDPRO” Rectangular Vibratory Screeners are applied to remove douclbe or triple uncut plastic strands from after cutting. Its removes fines as well. The screening decks are single piece with required perforation and have the facility for quick opening and assembly for fast and effective cleaning process. This equipment is usually installed with “INDPRO” Vibratory Spiral Conveyor.

b) Circular Vibratory Screener :- “INDPRO” Circular Flow Thru Screener gives many options like head room saving, portability and in line sieving option for dry bulk solids. They are tailor made machines available constructions are Carbon Steel, SS 304 / SS 316 with required finish.