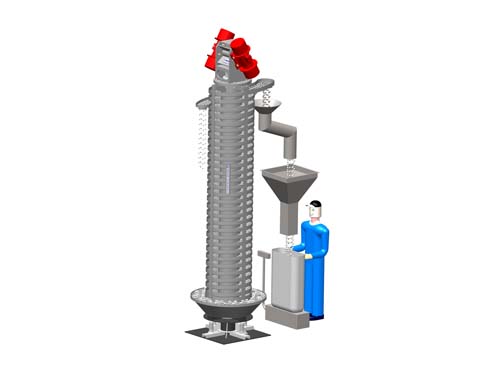

Vibratory Spiral Conveyor or Vibratory Spiral Elevator is a utility equipment for vertical conveying, against gravity, of Bulk Solids using mechanical vibration technology.

“INDPRO” Vibratory Spiral Conveyor is best engineered equipment to facilitate natural cooling or even heating of bulk solids like, plastic masterbatch or compounds / chemical/ food/ spices etc..

Though Design and Construction of “INDPRO” Vibratory Spiral Conveyor is extremely exhaustive and critical but the end result is a simple and user friendly machine for a complete ease of process’s operational requirements. Any semi skilled operator can handle it, once set.

Vibratory Motors installed to drive “INDPRO” Vibratory Spiral Conveyor are always from best in industry, from internationally well known makers, to give a really long trouble free operational life. Meeting the layout’s demand Vibrator Motors can be installed at top or bottom of the spiral track assembly, Vibratory Conveying capacity remains same in either of the cases.

Typical Benefits of using “INDPRO” Vibratory Spiral Conveyor are :-

- Compact foot prints

- Low Energy requirement

- Less Maintenance attentions

- Low sound emission

- Provides that required residence time for natural cooling and drying, replacing high noise and pollution generating Blowers / Cyclones / Trays etc. to make plant look compact, simple and dust free

- Special media cooling or heating is possible.

- High conveying capacities for some applications.

- No special skilled operator or tooling required for operation and maintenance

“INDPRO” Vibratory Spiral Conveyor for Plastics :-

Using “INDPRO” Vibratory Spiral Conveyor in Plastic Masterbatch / Glass Filled Thermoplastic Compounding / Thermosetting / Cable Compounds / Semi Conductive Compounds / Colour Masterbatch Lines, brings some great benefits for Natural Cooling and Drying so that the entire batch is uniformly conditioned to make superior quality and appearance improvement.

Filler Masterbatch Manufacturing Line :-

In India, “INDPRO” Vibratory Spiral Conveyor has proved a revolutionary technology to use in a filler masterbatch manufacturing line.

- A specially developed 3 in 1 variant for this industry offer – Natural Cooling, Drying & uniform Conditioning – condensation issue is eliminated

- Fines / Oversized particle removal

- Inline contamination free bagging – no trays / blowers / cyclones are required

Compounding / Colour masterbatch Manufacturing Line :-

In India, Compounding manufacturers trust on “INDPRO” Vibratory Spiral Conveyor for Cooling and Drying post Pelletizing. This industry need frequent cleaning friendly construction of the process equipment so the Spiral Flights profiles are specially developed to meet this requirement.

Vibratory Spiral Conveyor :- “INDPRO” Vibratory Spiral Conveyor is most effective solution for vertical lifting of Dry Bulk Solids. This equipment offers tailor made solutions for cooling or heating process requirement of plastic / chemical / food sectors.

Typical Benefits of using “INDPRO” Vibratory Spiral Conveyor are :-

- Uses very less Floor Space

- Low Energy requirement

- Less Maintenance attentions

- Low sound emission

- Provides that required residence time for natural cooling and drying, replacing high noise and pollution generating Blowers / Cyclones / Trays etc. To make plant look compact, simple and dustfree

- Special Media cooling or heating is possible.

- High capacities upto 4 TPH

- No special skilled operator or tools required for operation and maintenance

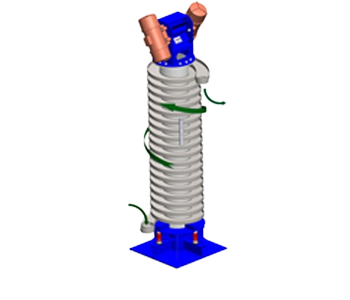

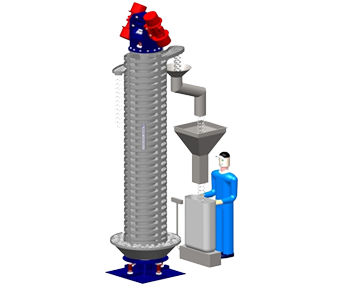

a) “INDPRO” Vibratory Spiral Conveyor to use in a filler masterbatch manufacturing line, removes fines and oversize particles online to facilitate direct bagging so that contamination and moisture gathering issues are prevented.

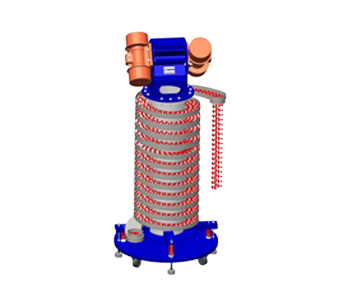

b) “INDPRO” Vibratory Spiral Conveyor to use in a Engineering Plastic Compounding line for natural cooling, drying and conditioning.

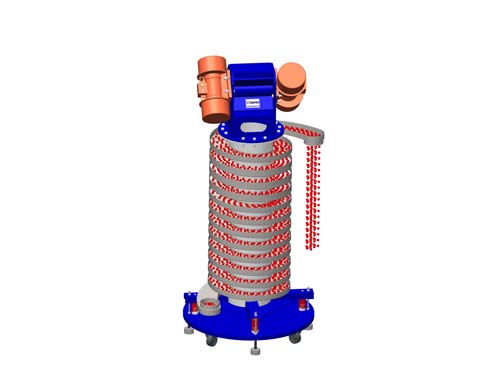

c) “INDPRO” Vibratory Spiral Conveyor to use in a Cable Compounding line with indirect cold water media cooling.

d) “INDPRO” Vibratory Spiral Conveyor to use in a PVC Compounding line with indirect cold water media cooling.